+86-18862679789

admin@evertopest.com

Metal composite panel production line is a manufacturing system that produces innovative building materials by bonding upper and lower metal sheets with intermediate layers - including polyethylene (PE), fire-resistant core materials (Class B/A fire-rated cores), corrugated cores, or 3D aluminum cores - through high-temperature and high-pressure processes using polymer adhesive films. These panels exhibit characteristics such as lightweight construction, weather resistance, fireproofing, sound insulation, and easy machinability. Widely applied in architectural curtain walls, interior decoration, advertising display boards, and vehicle compartments, they represent a versatile solution for modern construction and industrial applications.

In the modern panel manufacturing industry, waste management has transitioned from a logistical burden to a strategic opportunity. The Offline Crusher is an environmentally friend...

View MoreAs the global manufacturing sector shifts toward materials that offer both high durability and low environmental impact, the PVC Foam Composite Panel Production Line has emerged a...

View MoreIn the competitive world of high-end material fabrication, the transition from manual assembly to a fully automated Aluminum Honeycomb Composite Panel Production Line represents a...

View MoreIn the rapidly evolving landscape of modern aerospace, marine, and high-end construction, the demand for materials that offer extreme strength without the burden of weight has rea...

View MoreIn the fast-paced world of modern manufacturing and logistics, the difference between a profitable operation and a struggling one often comes down to how efficiently materials move...

View MoreMetal Composite Panel Production Line Series: Classification, Application and Core Advantages

The Metal Composite Panel Production Line Series is a set of professional intelligent equipment developed for the mass production of metal composite panels, which are widely used in architecture, transportation, and industrial fields. According to the functional positioning and application scenarios of the produced panels, the series can be clearly divided into three main categories, each with unique technical characteristics and targeted application directions, providing enterprises with precise production solutions.

I、Classification of Metal Composite Panel Production Line Series

1. Fire-Resistant Metal Composite Panel Production Line (A2/B1 Grade)

This type of production line is mainly used to manufacture metal composite panels with high fire resistance, and its core design focuses on ensuring the panel meets strict fire safety standards. Technically, it is equipped with a dedicated noncombustible core material processing module (suitable for mineral wool, cement fiberboard, etc.) and a high-temperature-resistant adhesive mixing system, which can avoid the release of toxic gases or melting and dripping of the panel during combustion. At the same time, the online fire performance detection unit is configured to conduct real-time sampling tests on semi-finished products—this design is in line with the requirements of the national standard 《Non-Combustible Metal Composite Panels for Architectural Decoration》, of which Zhangjiagang Hongyang Machinery Equipment Co., Ltd. is a drafting unit, ensuring that the produced panels can stably reach A2-grade noncombustible or B1-grade flame-retardant standards.

2. Decorative Metal Composite Panel Production Line (3D/Color Customized)

Focusing on the aesthetic and personalized needs of architectural decoration, this production line specializes in manufacturing metal composite panels with rich surface effects. It integrates a 3D embossing unit and a multi-color synchronous coating system: the 3D embossing unit can press patterns such as wood grain, stone grain, and geometric reliefs on the metal surface layer (aluminum coil, galvanized steel coil) with a pattern depth of 0.5-3mm; the multi-color coating system supports one-stop coating of 1-3 layers of paints (polyester, fluorocarbon, matte, etc.), and can achieve real-time color adjustment according to Pantone color cards, avoiding color differences caused by separate coating and compounding. In addition, it is also equipped with an ultra-thin panel forming module, which can produce panels with a minimum thickness of 2mm, meeting the installation needs of interior decoration scenarios with limited space.

3. Functional Metal Composite Panel Production Line (Honeycomb/Corrugated Core)

This category is designed for the production of metal composite panels with special functional properties (lightweight, high strength, sound insulation, etc.), and is divided into two sub-types according to the core structure of the panel:

Aluminum Honeycomb Core Metal Composite Panel Production Line: It can complete the entire process from the stretching of aluminum honeycomb cores (hexagonal cell side length 5-15mm adjustable) to the compound bonding with the metal surface layer. The honeycomb core structure makes the panel lightweight (30%-50% lighter than solid core panels) while maintaining high bending strength (≥25MPa), suitable for scenarios with strict weight requirements.

Corrugated Core Metal Composite Panel Production Line: It adopts a "waveform positioning + segmented pressing" process to bond the corrugated metal core (wave height 10-20mm) with the surface layer. The corrugated structure enhances the panel's impact resistance and sound insulation performance, and the production line can also be optionally equipped with a foam filling unit to further improve the thermal insulation effect of the panel.

II、Main Applications of Each Production Line

1. Application of Fire-Resistant Metal Composite Panel Production Line

The panels produced by this line are mainly used in scenarios with high fire safety requirements:

Architectural Field: Exterior wall curtain walls and interior partition walls of high-rise residential buildings, shopping malls, subway stations, and hospitals. For example, in high-rise buildings over 100 meters, A2-grade fire-resistant panels produced by this line can meet the mandatory fire protection requirements of national standards, effectively blocking the spread of fire between floors.

Industrial Field: Fire-resistant enclosures of power plants, chemical workshops, and data centers. The panels can withstand high temperatures of 800℃ or above for a short time, reducing the risk of equipment damage caused by fire.

2. Application of Decorative Metal Composite Panel Production Line

The decorative panels manufactured by this line are widely used in interior and exterior decoration scenarios that pursue aesthetics:

Interior Decoration: Wall panels and ceiling panels of high-end hotels, luxury residential buildings, and commercial stores. For example, 3D wood-grain decorative panels can simulate the texture of solid wood, creating a warm and natural interior atmosphere; fluorocarbon-coated color panels have strong weather resistance and are suitable for interior spaces with large people flow.

Exterior Decoration: Facade decoration of boutique shops, cultural centers, and exhibition halls. The colorful and personalized surface effects can make the building stand out, enhancing the brand image or cultural expression of the venue.

3. Application of Functional Metal Composite Panel Production Line

The functional panels produced by this line are mainly used in transportation and industrial scenarios with special performance requirements:

Aluminum Honeycomb Core Panel Application: Interior walls and floors of high-speed trains, cruise ships, and aircraft cabins. The lightweight feature of the panel can reduce the overall weight of the vehicle/ship, thereby saving energy consumption; at the same time, its high strength can withstand long-term vibration and impact during operation.

Corrugated Core Panel Application: Partition walls and sound insulation enclosures of industrial workshops, factory warehouses, and highway noise barriers. The corrugated structure's sound insulation amount can reach ≥45dB, effectively reducing industrial noise or traffic noise pollution; the panel's corrosion resistance also ensures long-term use in harsh industrial environments.

III、Core Advantages of the Series

The Metal Composite Panel Production Line Series has three core advantages that are widely recognized in the market:

First, strong adaptability supported by professional platforms: Supported by the Suzhou Engineering Technology Research Center and Jiangsu Provincial Graduate Workstation, Zhangjiagang Hongyang Machinery has established three technological platforms—precision transmission control, intelligent process systems, and modular design. Relying on these platforms, each production line in the series adopts a modular structure, allowing enterprises to add functional modules (such as fire-resistant, 3D embossing) to adjust product types without replacing the entire line.

Second, high production efficiency driven by intelligent technology: The series is equipped with an intelligent central control system developed based on Hongyang Machinery’s "intelligent process systems" platform. Integrating precision transmission control technology, it shortens parameter adjustment time by 60%, achieves a daily output of 800-2000㎡, and cuts equipment commissioning cycles by 30% compared to industry standards.

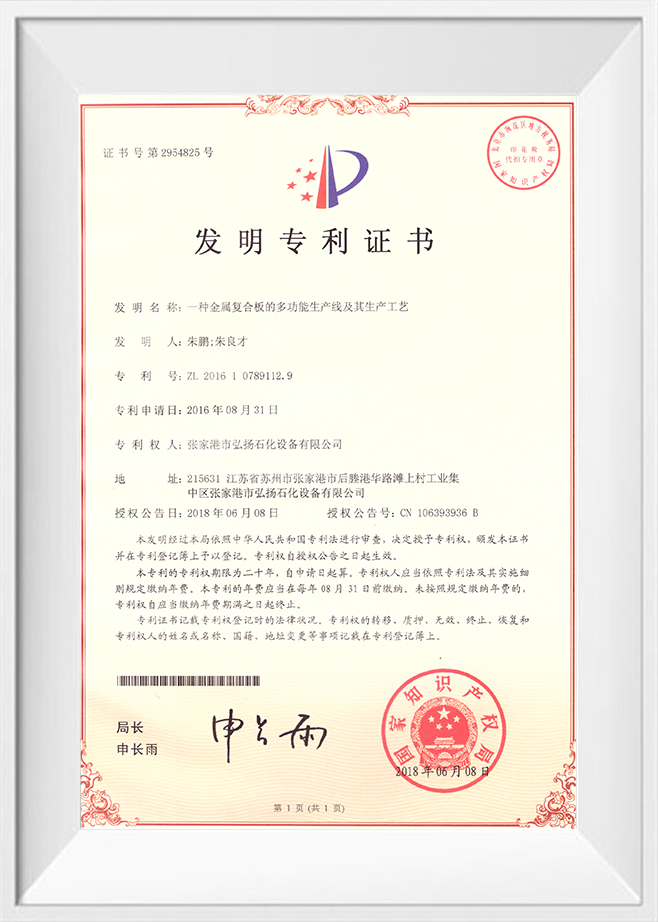

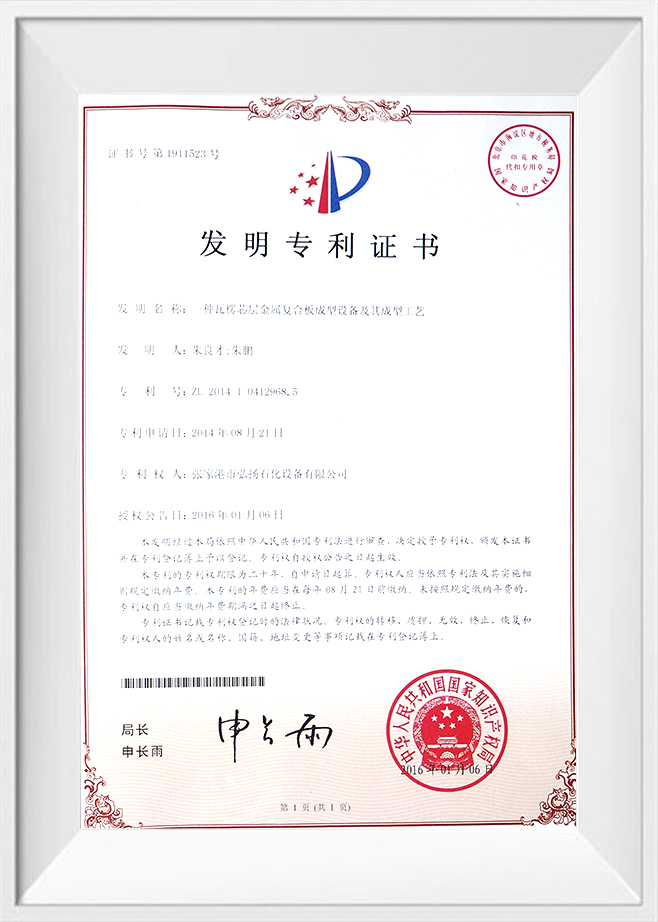

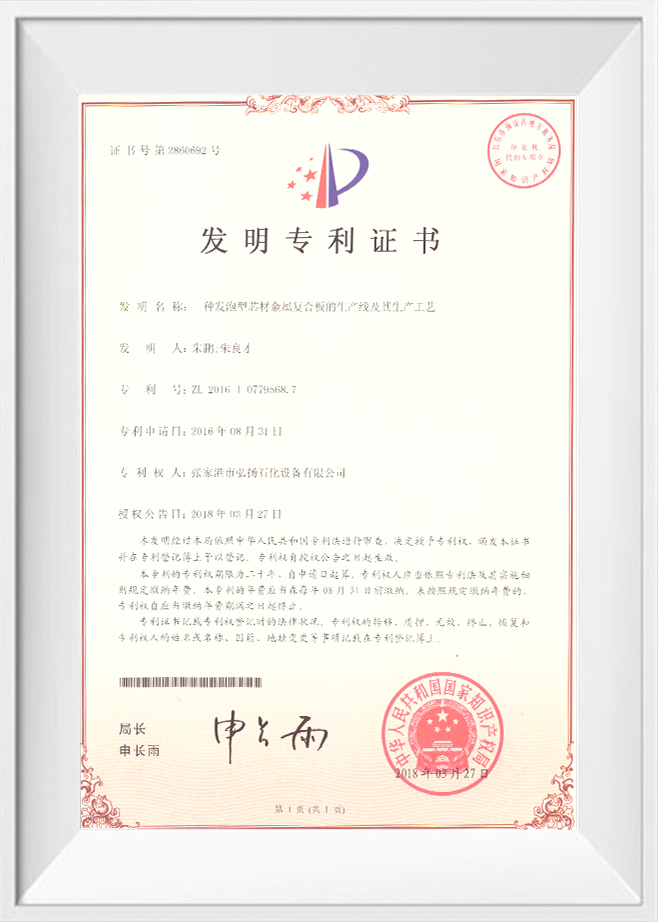

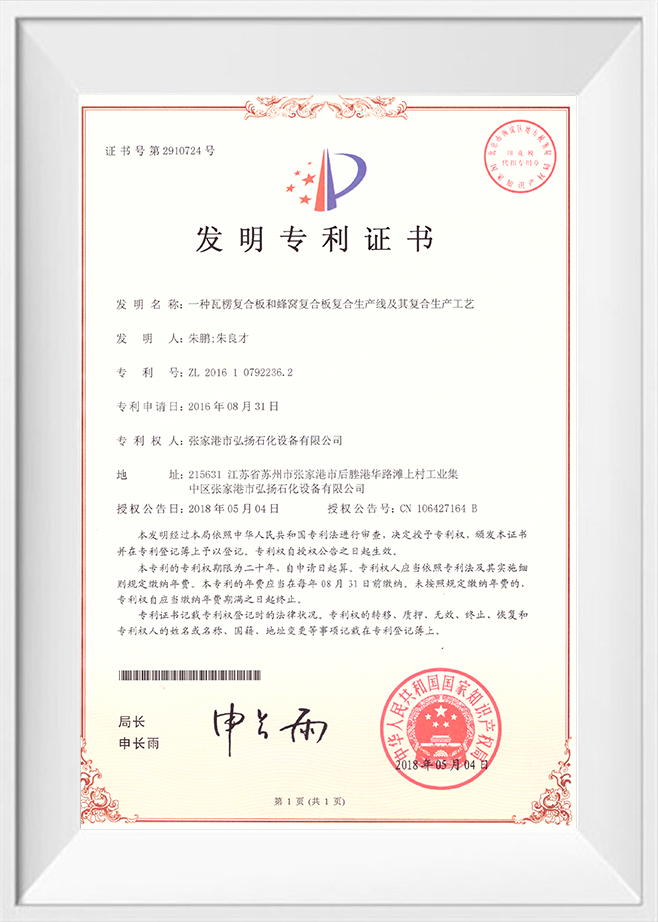

Third, global compliance guaranteed by enterprise strength: The production lines have passed ISO 9001 Quality Management System and CE Certification, meeting international standards (EU CE, US UL, ROHS). Backed by Hongyang Machinery’s technical strength and industry resources, the series has been exported to 45 countries and regions, trusted by 14 of the world’s top 20 metal composite material manufacturers.Up to now, the series has 70 core patents of Hongyang Machinery supporting technological iterations, providing a reliable path for enterprises to expand the global market.