+86-18862679789

admin@evertopest.com

In the modern panel manufacturing industry, waste management has transitioned from a logistical burden to a strategic opportunity. The Offline Crusher is an environmentally friend...

View MoreAs the global manufacturing sector shifts toward materials that offer both high durability and low environmental impact, the PVC Foam Composite Panel Production Line has emerged a...

View MoreIn the competitive world of high-end material fabrication, the transition from manual assembly to a fully automated Aluminum Honeycomb Composite Panel Production Line represents a...

View MoreIn the rapidly evolving landscape of modern aerospace, marine, and high-end construction, the demand for materials that offer extreme strength without the burden of weight has rea...

View MoreIn the fast-paced world of modern manufacturing and logistics, the difference between a profitable operation and a struggling one often comes down to how efficiently materials move...

View MoreAluminum Coil Color Coating Production Line: Structure, Technology and Application Value

The Aluminum Coil Color Coating Production Line is a key intelligent equipment for the surface treatment of aluminum coils, mainly used to apply uniform, durable and aesthetically pleasing coatings to aluminum coil surfaces. It is widely used in the upstream of the metal composite material industry, providing high-quality colored aluminum coil raw materials for the production of decorative metal composite panels, architectural curtain walls, home appliance shells and other products. With advanced coating technology and intelligent control capabilities, this production line has become an important support for enterprises to improve product added value and expand market segments.

I、Core Structure of the Production Line

The Aluminum Coil Color Coating Production Line is composed of five core functional units, which are closely connected to form a continuous and automated production process, ensuring the stability and consistency of coating quality:

1. Pretreatment Unit

This unit is the basis for ensuring coating adhesion. It mainly includes degreasing, pickling, passivation and drying modules: the degreasing module uses alkaline cleaning agents to remove oil stains and dust on the aluminum coil surface; the pickling module uses dilute acid solution to eliminate surface oxides and burrs, making the aluminum coil surface smooth; the passivation module forms a dense oxide film on the aluminum coil surface through chemical reaction, enhancing the bonding force between the aluminum coil and the coating; the drying module uses hot air circulation to dry the passivated aluminum coil, avoiding moisture affecting the subsequent coating process. The entire pretreatment process is controlled by a precision transmission system, and the aluminum coil runs at a uniform speed of 20-60m/min to ensure that each part is fully treated.

2. Coating Unit

As the core part of the production line, the coating unit adopts a roller coating process and is equipped with 1-3 coating stations to meet the needs of single-layer or multi-layer coating: each coating station is equipped with a precision coating roller and a scraper, which can control the coating thickness within 5-30μm (adjustable according to product requirements); the coating tank is equipped with a constant temperature system to maintain the coating viscosity stable, avoiding coating defects caused by temperature changes; at the same time, the unit is equipped with a waste gas collection device, which collects and treats the volatile organic compounds (VOCs) generated during the coating process in accordance with environmental protection standards.

3. Curing Unit

The curing unit is used to fully cure the coated aluminum coil and form a stable coating film. It adopts a tunnel-type oven with multi-zone temperature control: the temperature of each zone is set according to the coating type (polyester coating 180-220℃, fluorocarbon coating 230-260℃), and the temperature control accuracy is ±5℃; the oven is equipped with a hot air circulation and exhaust system to ensure uniform temperature inside the oven and timely discharge of volatile gases; the curing time is adjusted by controlling the aluminum coil running speed, generally 2-5 minutes, to ensure that the coating is fully cross-linked and cured, improving its wear resistance and weather resistance.

4. Cooling Unit

After curing, the aluminum coil surface temperature is as high as 200℃ or above, and the cooling unit is needed to reduce the temperature to room temperature to avoid coating deformation or adhesion during winding: the unit adopts air cooling + water cooling combined cooling method; the air cooling section first uses low-temperature air to pre-cool the aluminum coil, reducing the surface temperature to 80-100℃; the water cooling section uses a water-cooled roller to further cool the aluminum coil, ensuring that the final temperature is below 40℃; the cooling process is synchronized with the aluminum coil running speed to avoid water stains on the aluminum coil surface.

5. Winding Unit

The winding unit is used to wind the cooled colored aluminum coil into a roll for storage and transportation. It is equipped with a tension control system and a deviation correction system: the tension control system maintains a stable tension during winding, ensuring that the aluminum coil roll is neat and not loose; the deviation correction system uses a photoelectric sensor to detect the edge position of the aluminum coil and adjust the winding position in real time, ensuring that the deviation of the aluminum coil roll edge is within ±2mm; the unit can also be equipped with an automatic weighing and labeling device to record the weight, specification and production date of each roll of aluminum coil, facilitating product traceability.

II、Key Technical Advantages

1. High Coating Quality Guaranteed by Precision Control

Relying on Zhangjiagang Hongyang Machinery’s "precision transmission control" and "intelligent process systems" technological platforms (established with the support of the Suzhou Engineering Technology Research Center and Jiangsu Provincial Graduate Workstation), the production line realizes full-process precision control: the precision transmission system ensures that the aluminum coil runs at a uniform speed, avoiding coating thickness unevenness caused by speed fluctuations; the intelligent process monitoring system monitors the coating thickness, oven temperature and aluminum coil tension in real time, and automatically adjusts parameters when deviations occur, ensuring that the coating qualification rate reaches over 99%. The produced colored aluminum coil has uniform color (color difference ΔE ≤ 1), smooth surface (no pinholes, bubbles) and strong coating adhesion (cross-cut test grade ≥ 4B).

2. Strong Adaptability to Meet Diverse Needs

The production line adopts a modular design (one of Hongyang Machinery’s three technological platforms), which can be flexibly configured according to customer needs: for customers who need multi-color production, a color change module can be added to quickly switch between different coatings (color change time ≤ 30 minutes); for customers who pursue high-performance coatings, a fluorocarbon coating dedicated module can be configured to meet the needs of high-weather resistance products (such as outdoor architectural curtain walls); in addition, the production line can adapt to aluminum coils of different widths (1220-2440mm) and thicknesses (0.15-1.5mm), covering most market application scenarios.

3. Energy Conservation and Environmental Protection in Line with Industry Trends

In response to global environmental protection policies, the production line has made multiple optimizations in energy conservation and environmental protection: the curing oven adopts a heat recovery system, which recovers the waste heat generated during the curing process and uses it for preheating fresh air, reducing energy consumption by 20%-30% compared with traditional ovens; the coating unit is equipped with a VOCs treatment device (activated carbon adsorption + catalytic combustion), which makes the waste gas emission concentration meet the national standard (≤ 50mg/m³); the cooling unit uses circulating water, reducing water consumption by 50% compared with single-pass water cooling.

III、Application Scenarios of the Produced Colored Aluminum Coils

The colored aluminum coils produced by this production line have excellent performance and are widely used in the following fields:

1. Architectural Decoration Field

Exterior Wall Curtain Walls: Fluorocarbon-coated colored aluminum coils have excellent weather resistance (after 2000 hours of artificial aging test, the color change grade ≤ 1, gloss retention rate ≥ 90%), and are suitable for exterior wall curtain walls of high-rise buildings, shopping malls and cultural centers; the rich color options (such as silver gray, dark brown, sky blue) can meet the aesthetic needs of different architectural styles.

Interior Decoration: Polyester-coated colored aluminum coils have bright colors and low cost, and are used for interior wall panels, ceiling panels and partition panels of hotels, residential buildings and office buildings; the 3D embossed colored aluminum coils (cooperated with the decorative metal composite panel production line) can simulate wood grain, stone grain and other textures, creating a natural and comfortable interior environment.

2. Home Appliance Industry

Colored aluminum coils are used for the shells of refrigerators, air conditioners, washing machines and other home appliances: the coating has good wear resistance (abrasion resistance test ≥ 500 cycles) and stain resistance (stain removal rate ≥ 95%), and can maintain a clean and beautiful appearance for a long time; at the same time, the aluminum coil has good thermal conductivity, which helps to improve the heat dissipation efficiency of home appliances.

3. Transportation Industry

In the transportation industry, colored aluminum coils are used for the outer skins of buses, RVs and train carriages: the lightweight characteristics of aluminum coils (density 2.7g/cm³) can reduce the vehicle weight and save energy consumption; the coating has good impact resistance (impact test ≥ 50cm) and corrosion resistance (salt spray test ≥ 1000 hours), which can withstand the harsh environment during vehicle operation.

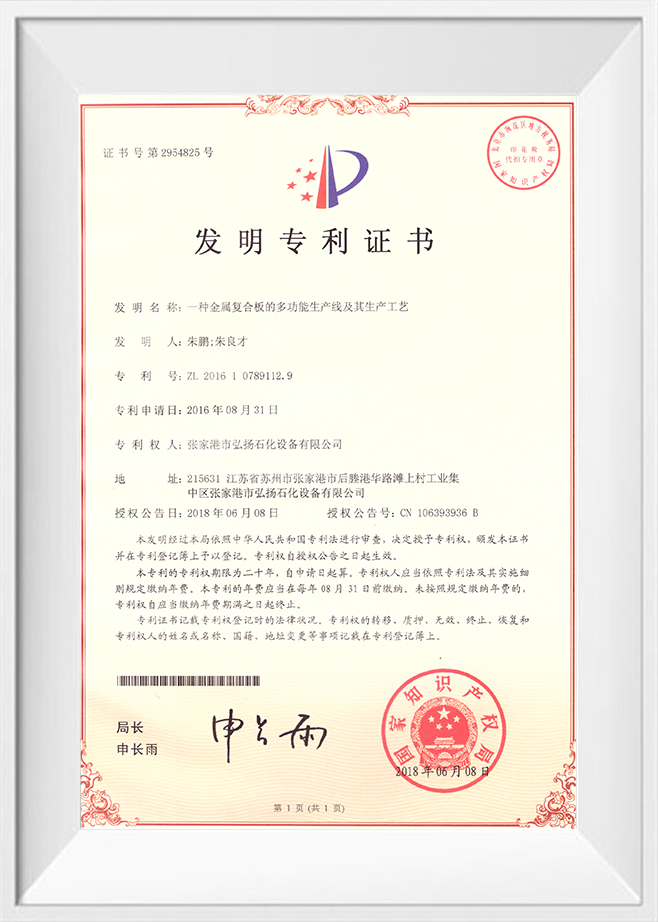

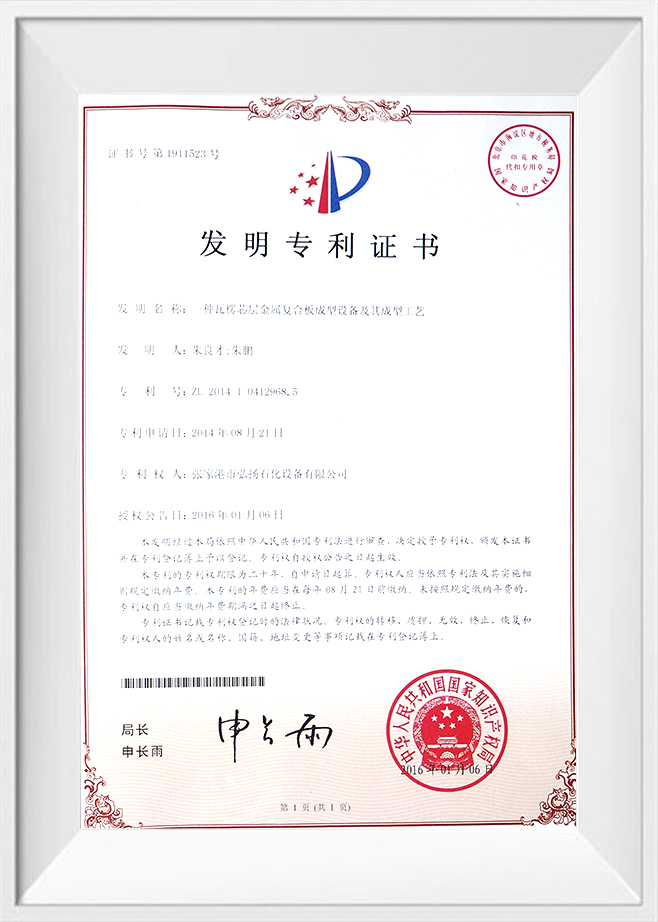

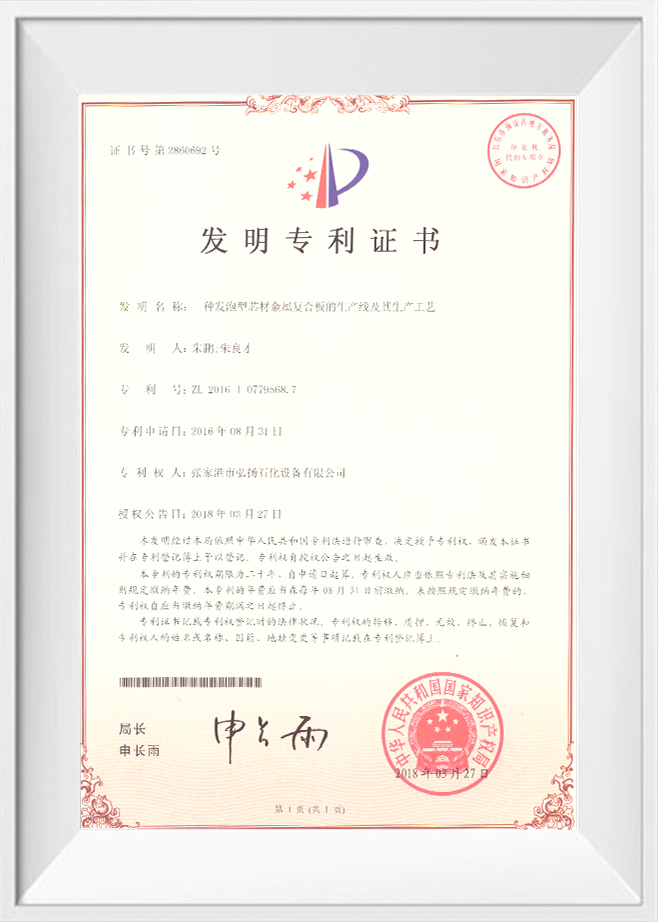

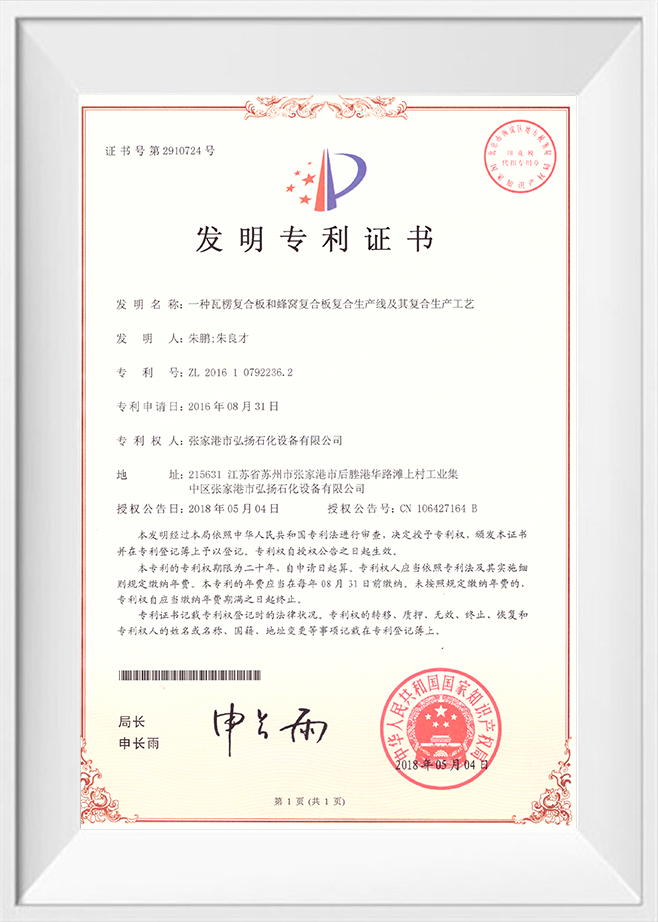

IV、Enterprise Support for the Production Line

As a national enterprise specializing in the R&D and manufacturing of intelligent equipment for metal composite materials, Zhangjiagang Hongyang Machinery provides comprehensive support for the Aluminum Coil Color Coating Production Line: the production line is designed and manufactured in accordance with ISO 9001 Quality Management System standards, and has passed CE Certification, ensuring that it meets international quality and safety requirements; the company provides a 48-hour global emergency response service, and dispatches engineers to the site for installation guidance, commissioning and operator training; relying on 70 core patents and technical accumulation in the field of metal composite equipment, the company can also provide customized modification services for the production line according to customer special needs. Up to now, this production line has been exported to Europe, the Middle East, Southeast Asia and other regions, serving many well-known metal processing enterprises and helping customers improve product competitiveness.