+86-18862679789

admin@evertopest.com

In the modern panel manufacturing industry, waste management has transitioned from a logistical burden to a strategic opportunity. The Offline Crusher is an environmentally friend...

View MoreAs the global manufacturing sector shifts toward materials that offer both high durability and low environmental impact, the PVC Foam Composite Panel Production Line has emerged a...

View MoreIn the competitive world of high-end material fabrication, the transition from manual assembly to a fully automated Aluminum Honeycomb Composite Panel Production Line represents a...

View MoreIn the rapidly evolving landscape of modern aerospace, marine, and high-end construction, the demand for materials that offer extreme strength without the burden of weight has rea...

View MoreIn the fast-paced world of modern manufacturing and logistics, the difference between a profitable operation and a struggling one often comes down to how efficiently materials move...

View MoreFR ACP Panel: Fire-Retardant Excellence for Diverse Applications

1. What is the core difference between FR ACP Panel and ordinary ACP Panel, and why is its fire-retardant performance critical?

The biggest difference between FR ACP Panel and ordinary ACP Panel lies in the core material and adhesive: ordinary ACP Panels usually use flammable organic cores (such as common polyethylene), which are easy to burn and release toxic gases when encountering fire; while FR ACP Panels adopt non-combustible or flame-retardant cores (such as modified mineral wool, inorganic cement fiber) and fire-resistant inorganic adhesives, which can meet the A2-grade non-combustible or B1-grade flame-retardant standards specified in GB 8624-2012.

This fire-retardant performance is not only a "compliance requirement" but also a "safety guarantee"—in high-rise building exterior walls or subway station interiors, once a fire breaks out, FR ACP Panels will not support combustion or spread flames, and will not release toxic fumes (such as carbon monoxide, hydrogen cyanide) that threaten personnel escape. For example, in a 100-meter-high residential building, the FR ACP Panel exterior wall can block the vertical spread of fire for more than 120 minutes, providing valuable time for fire rescue.

2. What performance indicators should be focused on when selecting FR ACP Panel, besides fire-retardant grade?

In addition to confirming the fire-retardant grade (A2/B1), three key performance indicators need to be paid attention to, which directly affect the service life and safety of the panel:

Bonding strength: The bonding strength between the aluminum surface layer and the core material should be ≥1.2MPa (tested according to GB/T 22412). If the bonding strength is insufficient, the panel may delaminate in high-temperature or humid environments, exposing the core material and reducing fire safety.

Weather resistance: The aluminum surface layer should be coated with fluorocarbon or high-quality polyester paint, with a gloss retention rate of ≥90% after 2000 hours of artificial aging test. This ensures that the panel will not fade, peel, or crack when used outdoors for a long time (such as shopping mall facades), avoiding the need for frequent replacement.

Mechanical strength: The bending strength should be ≥25MPa, and the impact resistance should reach ≥50cm (falling ball impact test). For industrial workshop partitions or indoor high-traffic areas, sufficient mechanical strength can prevent the panel from being damaged by external impacts and affecting its fire-retardant integrity.

3. In which specific scenarios is FR ACP Panel most suitable, and what are the installation precautions?

FR ACP Panel is widely used in three types of scenarios, and corresponding installation precautions need to be taken for different scenarios:

High-rise building exterior walls (A2-grade required): When installing, it is necessary to use fire-resistant keels (such as galvanized steel keels with a thickness of ≥1.5mm) and fill fire-resistant rock wool between the panels. The gap between panels should be sealed with fire-resistant sealant (not ordinary silicone sealant), to prevent flames from spreading through the gaps.

Public venue interiors (B1/A2-grade optional): For subway stations, hospitals, and hotel lobbies, the panel should be installed with a "dry hanging method" to avoid using flammable adhesives for pasting. At the same time, the joint between the panel and the ceiling/wall should be reserved with a 5-10mm expansion gap to prevent the panel from deforming and cracking due to temperature changes.

Industrial workshop partitions (A2-grade preferred): Since industrial workshops may have oil fumes or corrosive gases, the panel surface should be cleaned regularly (using neutral cleaning agents) to avoid chemical reactions that damage the coating. In addition, the installation height of the partition should be ≥2.5 meters, and fire-fighting accesses should not be blocked.

4. How to identify the authenticity of FR ACP Panel to avoid buying fake and inferior products?

There are three simple and effective identification methods, which can help distinguish between genuine and fake FR ACP Panels:

Check the test report: Request the supplier to provide a formal fire-retardant performance test report (issued by a national recognized testing institution), and verify the report number on the official website of the testing institution. Fake products often only have "certificates of conformity" issued by the manufacturer, without authoritative test reports.

Sampling combustion test: Take a small piece of the panel core material (50×50mm) and ignite it with a lighter. The core material of genuine A2-grade FR ACP Panel will not burn, and will self-extinguish immediately after leaving the fire source, with no dripping; the core material of fake products will burn violently, with black smoke and molten dripping.

Check the product marking: Genuine FR ACP Panels will clearly mark the fire-retardant grade (such as "A2" or "B1"), production date, and manufacturer information on the back of the panel; fake products often have vague markings or even no markings.

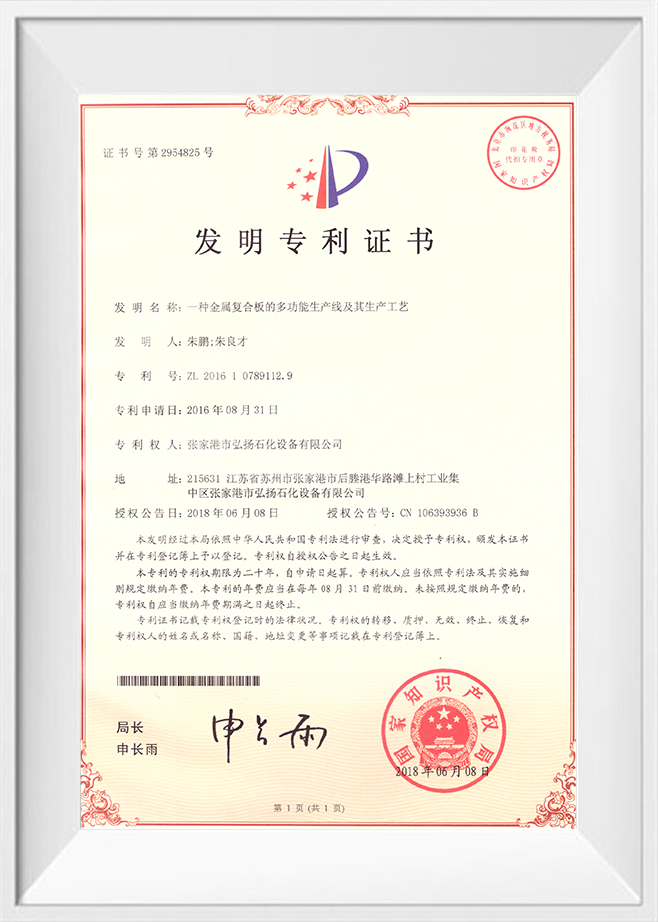

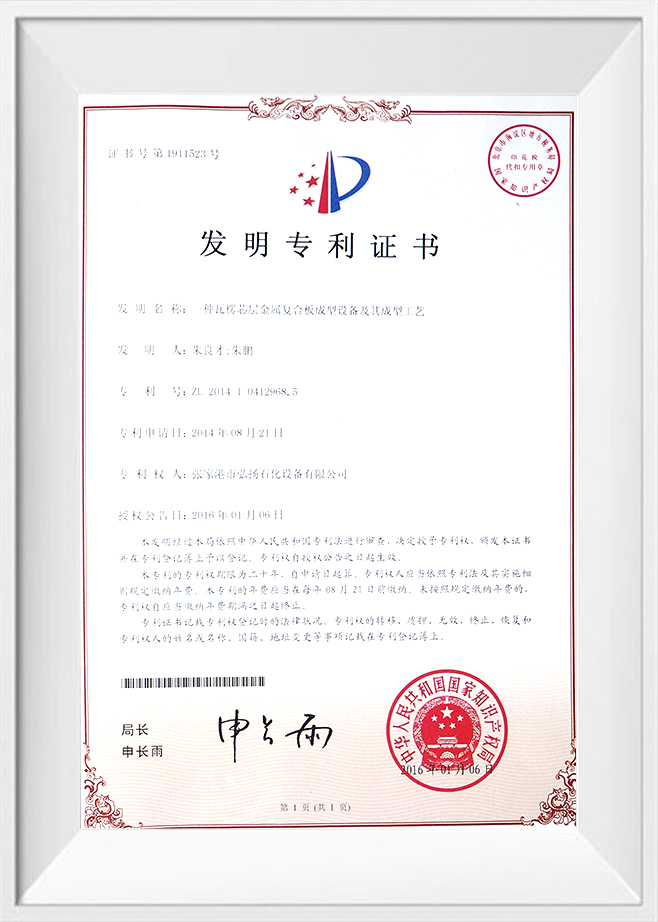

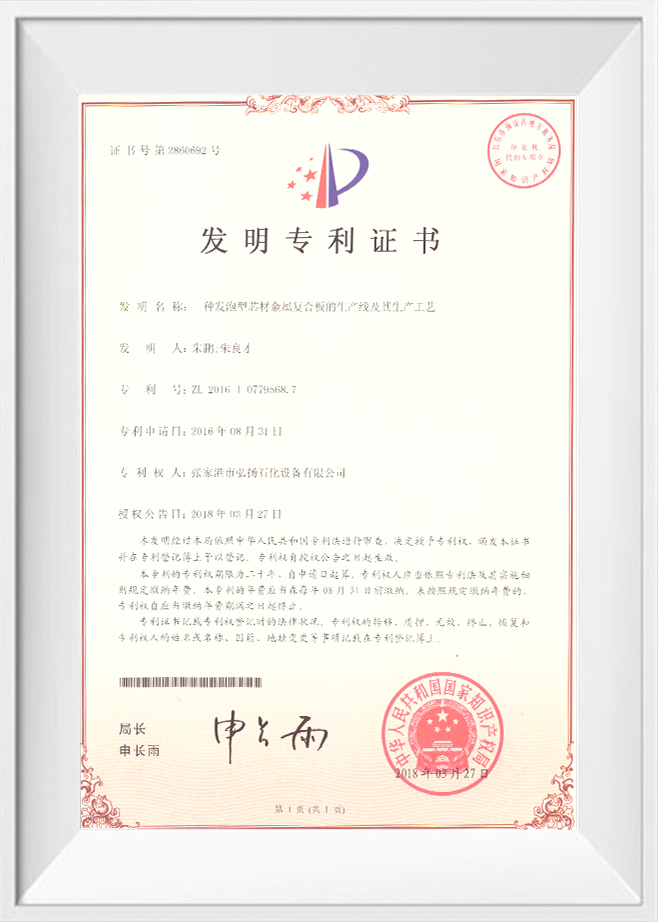

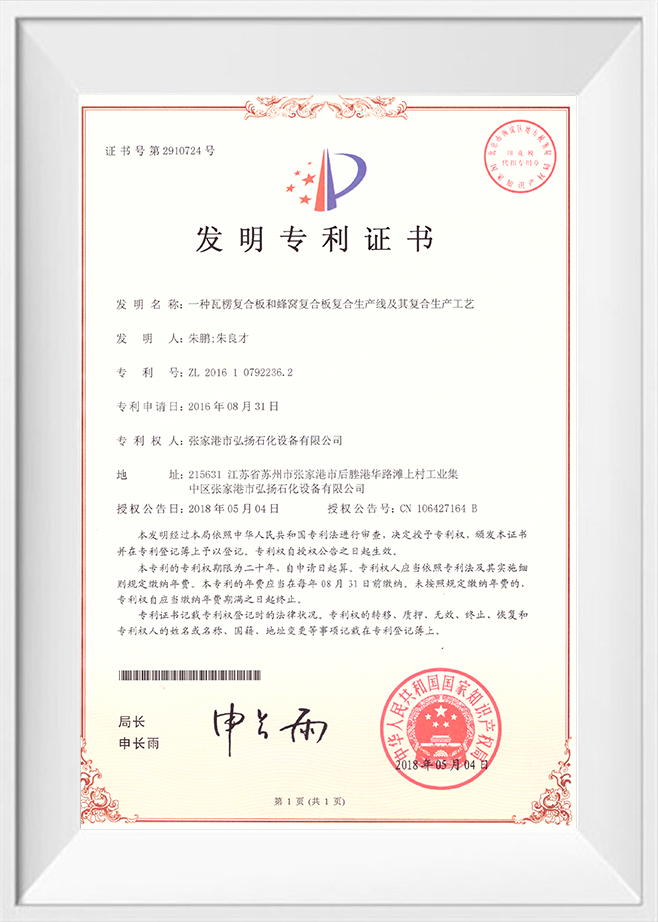

In the FR ACP Panel industry, the quality of the product is closely related to the production equipment of the manufacturer. Zhangjiagang Hongyang Machinery, as a drafter of national fireproof panel standards, has developed a dedicated FR ACP Panel production line, which integrates precision core material compounding, online fire-retardant performance detection, and high-temperature curing technologies. The line can ensure that the produced FR ACP Panels meet A2/B1-grade standards stably, and has provided production equipment support for many well-known FR ACP Panel manufacturers at home and abroad. At the same time, the company can also provide customers with raw material selection guidance and installation technical training, forming a one-stop service from equipment to product application.