+86-18862679789

admin@evertopest.com

In the modern panel manufacturing industry, waste management has transitioned from a logistical burden to a strategic opportunity. The Offline Crusher is an environmentally friend...

View MoreAs the global manufacturing sector shifts toward materials that offer both high durability and low environmental impact, the PVC Foam Composite Panel Production Line has emerged a...

View MoreIn the competitive world of high-end material fabrication, the transition from manual assembly to a fully automated Aluminum Honeycomb Composite Panel Production Line represents a...

View MoreIn the rapidly evolving landscape of modern aerospace, marine, and high-end construction, the demand for materials that offer extreme strength without the burden of weight has rea...

View MoreIn the fast-paced world of modern manufacturing and logistics, the difference between a profitable operation and a struggling one often comes down to how efficiently materials move...

View MoreIndustry Knowledge About A Grade Noncombustible Fireproof Composite Panel Production Line

In the field of architectural and industrial fireproof materials, the A grade noncombustible fireproof composite panel production line is a key equipment that directly affects product quality and market compliance. Below, we will sort out core industry knowledge through a question-and-answer approach to help you gain a comprehensive understanding of this equipment.

1. What is the core standard for defining "A grade noncombustible" in the production of fireproof composite panels, and why is it crucial for production lines?

The "A grade noncombustible" attribute of fireproof composite panels is mainly based on the national standard GB 8624-2012《Classification of Burning Behavior of Building Materials and Products》. According to this standard, A grade noncombustible materials refer to materials that do not burn in the event of a fire, do not release toxic or harmful gases, and have a very low heat release rate. For production lines, complying with this standard is not just a "qualification threshold"—it directly determines whether the produced panels can be used in high-risk scenarios such as high-rise buildings, public venues, and industrial workshops.

To meet this standard, production lines need to achieve precise control over multiple links: from the selection of noncombustible core materials (such as mineral wool, rock wool, or inorganic composite materials) to the use of fire-resistant adhesives that do not produce toxic fumes when heated, and even the temperature and pressure parameters during the composite pressing process. If any link deviates, the panel may fail to meet the A grade noncombustible requirement, leading to product waste or potential safety hazards in subsequent applications.

2. What core technical configurations are required for an A grade noncombustible fireproof composite panel production line to ensure stable product quality?

Stable production of A grade noncombustible fireproof composite panels cannot be achieved without three core technical configurations:

First, intelligent process monitoring systems. Since the noncombustible performance of panels is highly sensitive to process parameters, the production line needs real-time detection modules (such as temperature sensors, pressure transmitters, and flame retardancy pre-test devices) to monitor the bonding temperature (usually 180-220℃ for A grade products), pressing pressure (0.8-1.2MPa), and curing time in real time. Once parameters deviate, the system can automatically adjust to avoid problems such as insufficient bonding or core material carbonization that affect fire resistance.

Second, precision transmission and cutting mechanisms. A grade noncombustible panels have strict requirements for thickness uniformity (allowable error ≤±0.3mm) and edge flatness. The production line needs servo-driven transmission systems to ensure synchronous feeding of metal surface layers and core materials, and CNC double-sided cutting machines to achieve high-precision cutting (accuracy ±0.5mm). This not only ensures the appearance quality of the panels but also avoids gaps at the edges that may reduce fire resistance.

Third, modular raw material pretreatment units. The metal surface layers (aluminum coils or galvanized steel coils) of A grade panels need to undergo degreasing, pickling, and passivation to remove oil stains and oxides—otherwise, the bonding strength with the core material will decrease, and water vapor may penetrate over time to damage the noncombustible core material. The modular design allows the pretreatment unit to be flexibly adjusted according to the type of surface material, ensuring compatibility with different raw material characteristics.

3. In the current market, what pain points can A grade noncombustible fireproof composite panel production lines solve for enterprises?

For enterprises engaged in the production of fireproof composite materials, the A grade noncombustible fireproof composite panel production line mainly solves three core pain points:

The first pain point is market access barriers. With the gradual strictness of fire safety regulations in various countries (such as the requirement for A grade noncombustible materials in Chinese high-rise building exterior walls), enterprises that cannot produce A grade products will be excluded from key markets. The production line directly provides a compliant production solution, helping enterprises obtain access to high-end markets such as commercial real estate and public infrastructure.

The second pain point is low production efficiency and high waste rate. Traditional semi-automatic production methods often require manual adjustment of parameters, leading to a product qualification rate of only 85%-90%. The fully automated A grade production line can achieve a qualification rate of over 98%, and the production cycle per panel is shortened to 3-5 minutes (20%-30% faster than traditional lines), significantly reducing raw material waste and labor costs.

The third pain point is difficulty in balancing fire resistance and other properties. Many enterprises once faced the problem that "pursuing A grade noncombustible performance leads to reduced mechanical strength or thermal insulation of panels". The advanced composite technology of professional A grade production lines (such as optimizing the ratio of core materials and adhesives) can ensure that while meeting A grade fire resistance, the panels still have excellent bending strength (≥25MPa) and thermal insulation performance (thermal conductivity ≤0.035W/(m·K)), meeting the comprehensive needs of architectural applications.

4. How to judge whether an A grade noncombustible fireproof composite panel production line has long-term market competitiveness?

Judging the long-term competitiveness of the production line mainly depends on two aspects: compatibility with future standards and after-sales support capabilities.

In terms of standard compatibility, fire safety standards are constantly updated (such as the possible increase in requirements for smoke toxicity of A grade materials in the future). The production line needs to have upgrade potential—for example, the control system can be upgraded to adapt to new testing indicators, or the core material feeding module can be adjusted to accommodate new types of noncombustible core materials. This avoids the situation where the equipment becomes obsolete due to standard updates in 3-5 years.

In terms of after-sales support, the production line involves multiple professional links such as electrical control and mechanical debugging. Enterprises need to choose equipment providers that can provide timely technical support—such as 48-hour emergency response, on-site training for operators (especially for quality control points of A grade products), and regular maintenance guidance. Some equipment providers in the market have also accumulated rich experience in international markets, and their production lines have passed CE, ISO 9001 and other certifications, which can help enterprises smoothly export products to Europe, the Middle East and other regions.

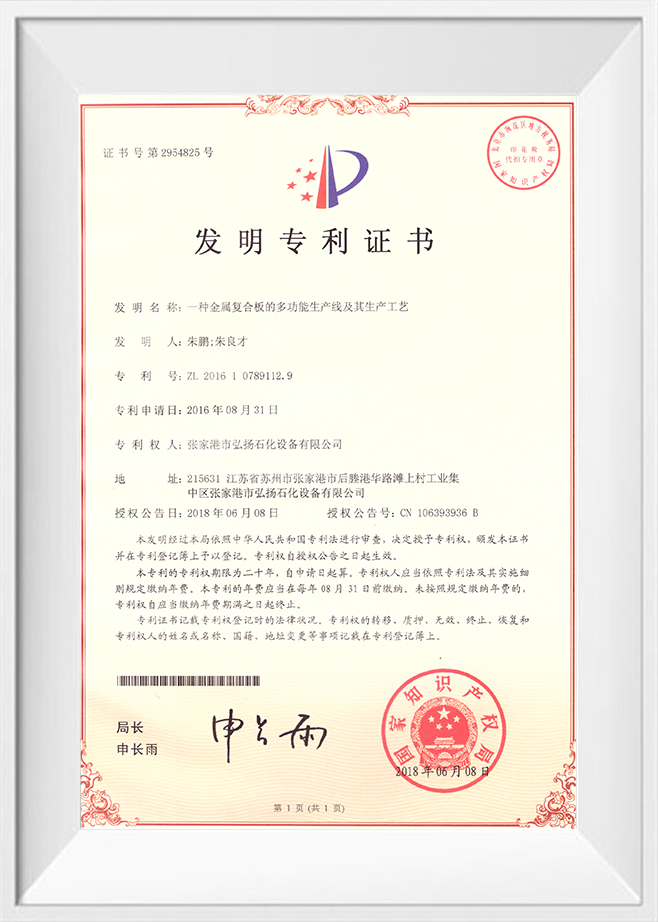

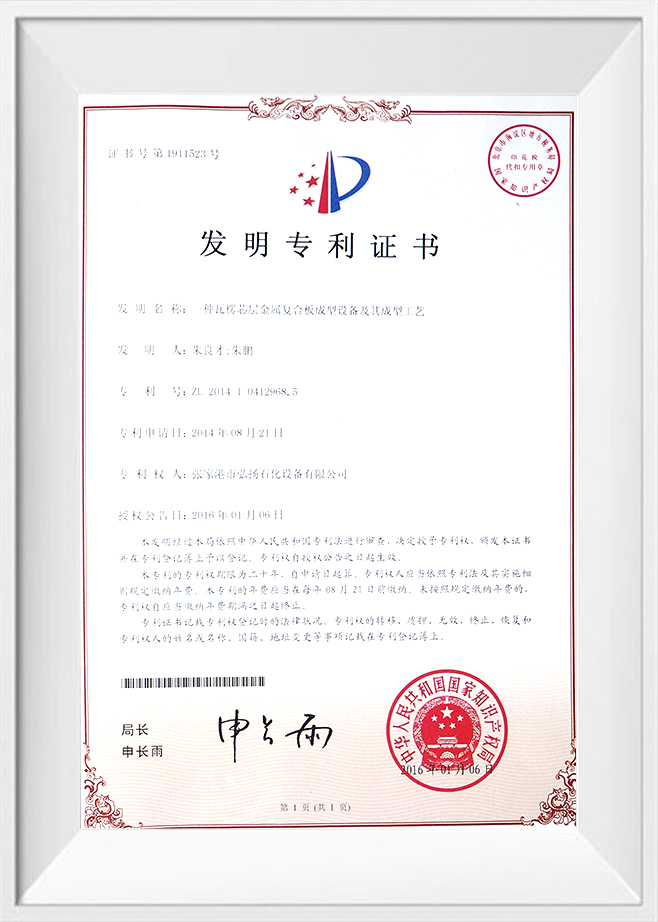

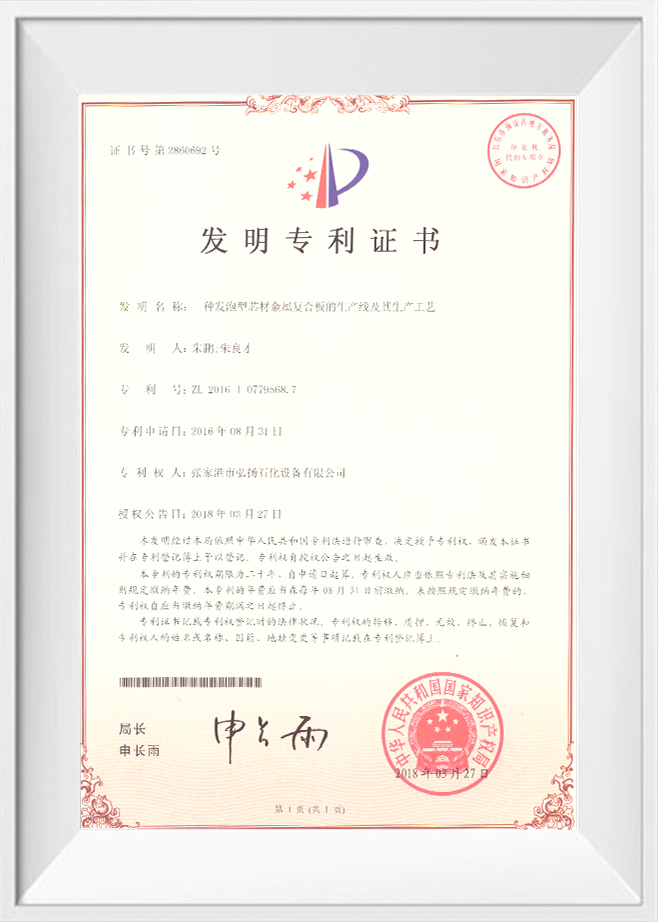

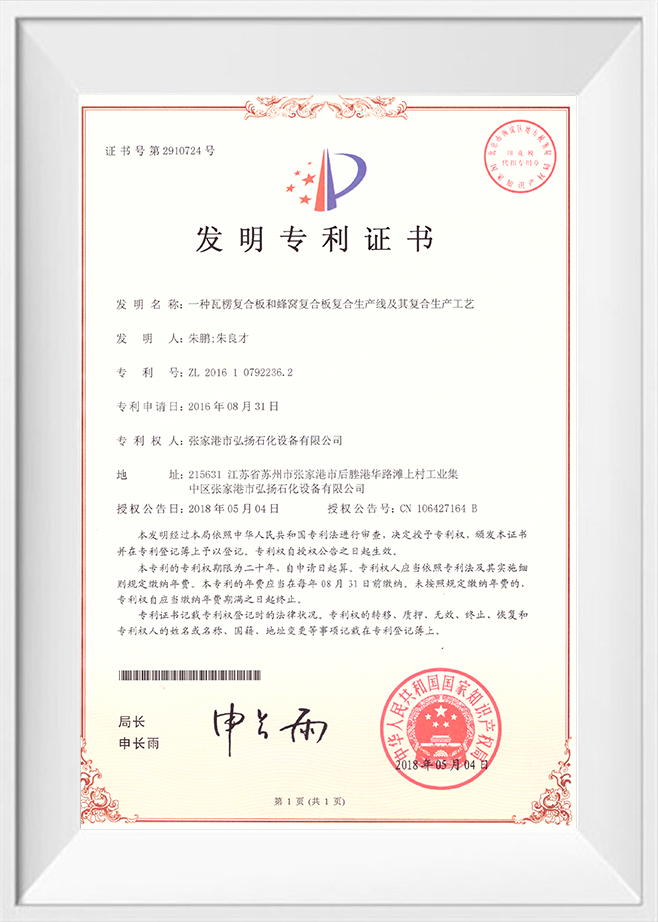

In the current industry, some enterprises with long-term R&D accumulation have formed mature solutions in the field of A grade noncombustible fireproof composite panel production lines. They not only have core patents in precision control and intelligent processes but also have exported equipment to more than 40 countries and regions, helping many customers achieve stable production of A grade products. This kind of practical experience not only reflects the reliability of the equipment but also provides enterprises with a reference for choosing partners.