+86-18862679789

admin@evertopest.com

In the modern panel manufacturing industry, waste management has transitioned from a logistical burden to a strategic opportunity. The Offline Crusher is an environmentally friend...

View MoreAs the global manufacturing sector shifts toward materials that offer both high durability and low environmental impact, the PVC Foam Composite Panel Production Line has emerged a...

View MoreIn the competitive world of high-end material fabrication, the transition from manual assembly to a fully automated Aluminum Honeycomb Composite Panel Production Line represents a...

View MoreIn the rapidly evolving landscape of modern aerospace, marine, and high-end construction, the demand for materials that offer extreme strength without the burden of weight has rea...

View MoreIn the fast-paced world of modern manufacturing and logistics, the difference between a profitable operation and a struggling one often comes down to how efficiently materials move...

View MoreAuxiliary Equipment for Metal Composite Material Production: Classification, Functions and Supporting Value

Auxiliary Equipment refers to the professional supporting equipment that cooperates with core production lines (such as Metal Composite Panel Production Lines, Aluminum Coil Color Coating Production Lines) to ensure the smooth progress of the entire production process, improve production efficiency and product quality. As an important part of the metal composite material production system, these equipments cover links such as raw material handling, quality detection, finished product packaging and waste treatment, and play a "linking" and "guaranteeing" role in the industrial chain. Relying on Zhangjiagang Hongyang Machinery’s technological accumulation in precision control and modular design, its independently developed auxiliary equipment has strong compatibility with core production lines, forming a complete and efficient production solution.

I、Classification and Core Functions of Auxiliary Equipment

According to the production process links, Auxiliary Equipment can be divided into four categories: raw material pretreatment auxiliary equipment, production process auxiliary equipment, quality detection auxiliary equipment and finished product post-processing auxiliary equipment. Each category has targeted functions to solve practical pain points in different production links.

1. Raw Material Pretreatment Auxiliary Equipment

This type of equipment is mainly used to process raw materials (aluminum coils, steel coils, core materials) before entering the core production line, ensuring that the raw materials meet the feeding requirements and reducing the failure rate of the core line.

Coil Decoiling & Straightening Machine: Aimed at the problem of coil deformation during storage and transportation, this equipment uses a hydraulic expansion shaft to fix the coil, and cooperates with a multi-roller straightening system to flatten the curved aluminum/steel coil. The straightening accuracy can reach ±0.1mm/m, ensuring that the raw material enters the core line in a flat state and avoiding uneven composite bonding caused by material warping. It is compatible with coils of different widths (1220-2440mm) and weights (max 5t), and can be connected with the core line’s feeding system to realize continuous feeding.

Core Material Cutting & Trimming Machine: For inorganic noncombustible core materials (mineral wool, cement fiberboard) used in fire-resistant composite panels, this machine adopts a CNC cutting system to cut the core material into specified sizes (length 2000-6000mm, width 1220-2440mm) with a cutting error of ≤±0.5mm. At the same time, the edge trimming module can polish the cut surface to remove burrs, ensuring tight fitting between the core material and the metal surface layer during compounding. The equipment is equipped with a dust collection device to collect cutting dust and meet environmental protection requirements.

2. Production Process Auxiliary Equipment

These equipments run synchronously with the core production line to optimize the production process, improve efficiency and reduce manual intervention.

Automatic Glue Mixing & Feeding Machine: Matching the composite bonding link of the metal composite panel production line, this machine can automatically mix fire-resistant adhesives or decorative adhesives according to the set ratio (mixing accuracy ±1%). The glue storage tank is equipped with a constant temperature and stirring system to maintain the glue viscosity stable (avoiding glue solidification or delamination). The pipeline-type feeding design can directly connect to the core line’s glue coating unit, realizing continuous and uniform glue supply, and reducing the glue waste rate by 15% compared with manual feeding.

Tension Control Auxiliary Device: Installed in the aluminum coil color coating production line’s coating and curing links, this device uses a servo motor to adjust the tension of the aluminum coil in real time (tension adjustment range 50-500N). It can automatically compensate for tension changes caused by coil diameter reduction during operation, ensuring that the aluminum coil does not wrinkle or break during coating and curing. The device is connected with the core line’s intelligent control system to realize data synchronization and parameter linkage.

3. Quality Detection Auxiliary Equipment

This category is used to conduct real-time or sampling detection of semi-finished and finished products, ensuring that the products meet quality standards and avoiding unqualified products from entering the market.

Online Coating Thickness Detector: Suitable for the aluminum coil color coating production line, this detector uses a non-contact laser thickness measurement technology to detect the coating thickness of the aluminum coil in real time (detection range 5-30μm, accuracy ±0.5μm). It can automatically mark the positions with abnormal thickness and send an alarm to the core line’s control system, prompting parameter adjustment. The detection data is automatically stored in the system, which is convenient for product quality traceability.

Fire Resistance Sampling Tester: Matching the fire-resistant metal composite panel production line, this tester can take samples from semi-finished panels (sample size 300×300mm) and conduct a 10-minute high-temperature flame test (simulating GB 8624-2012 standard). It can automatically record the temperature change of the panel backside and whether there is melting or dripping, quickly judging whether the panel meets A2/B1-grade fire resistance requirements. The sampling process is automated, avoiding manual operation errors and improving detection efficiency.

4. Finished Product Post-Processing Auxiliary Equipment

These equipments are used for packaging, handling and storage of finished metal composite panels or colored aluminum coils, ensuring product integrity during transportation and storage.

Automatic Panel Stacking Machine: Connected to the cutting link of the metal composite panel production line, this machine uses a mechanical arm to grab the cut finished panels (max weight 50kg/piece) and stack them neatly. The stacking height can be adjusted (max 1.5m), and the stacking position accuracy is ±2mm. It is equipped with a protective film wrapping function to prevent scratches on the panel surface during stacking. Compared with manual stacking, it improves efficiency by 3 times and reduces labor intensity.

Coil Wrapping & Weighing Machine: For finished colored aluminum coils, this machine can automatically wrap the coil with stretch film (wrapping layer number 3-5 layers) to prevent moisture and dust. The built-in weighing sensor can accurately measure the coil weight (measurement range 100-5000kg, accuracy ±1kg) and print the weight, specification and production date on the label, which is pasted on the coil automatically. The wrapped coil is easy to load, unload and store, reducing transportation damage.

II、Core Advantages of Auxiliary Equipment

1. Strong Compatibility with Core Lines

Relying on Zhangjiagang Hongyang Machinery’s three technological platforms (precision transmission control, intelligent process systems, modular design), the auxiliary equipment is developed in conjunction with the core production lines. The interface size, control protocol and operation parameters are fully matched with the core lines, avoiding compatibility problems caused by mixing equipments from different manufacturers. For example, the automatic glue mixing machine can directly connect to the composite panel production line’s glue coating unit without additional modification, realizing "plug-and-play".

2. High Intelligence Reduces Manual Dependence

Most auxiliary equipments are equipped with intelligent control systems: the online coating thickness detector can automatically detect and alarm; the automatic panel stacking machine can realize unmanned operation; the tension control auxiliary device can automatically adjust parameters according to the core line’s operation status. These functions reduce manual intervention, avoid human errors (such as manual sampling detection errors, manual stacking irregularities) and improve production stability. The equipment’s operation interface is unified with the core line’s control system, which is convenient for operators to master.

3. Customizable to Meet Diverse Needs

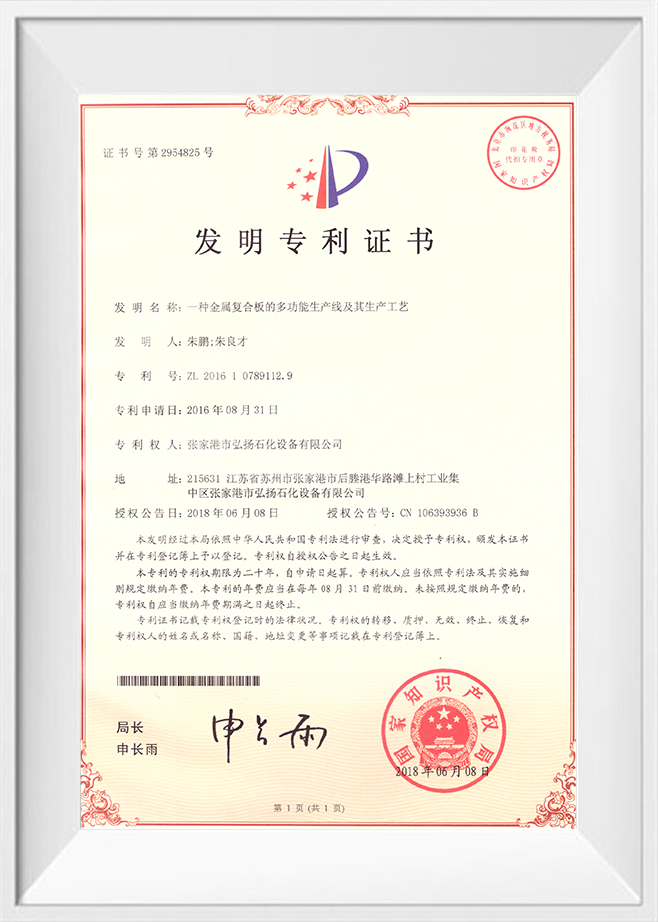

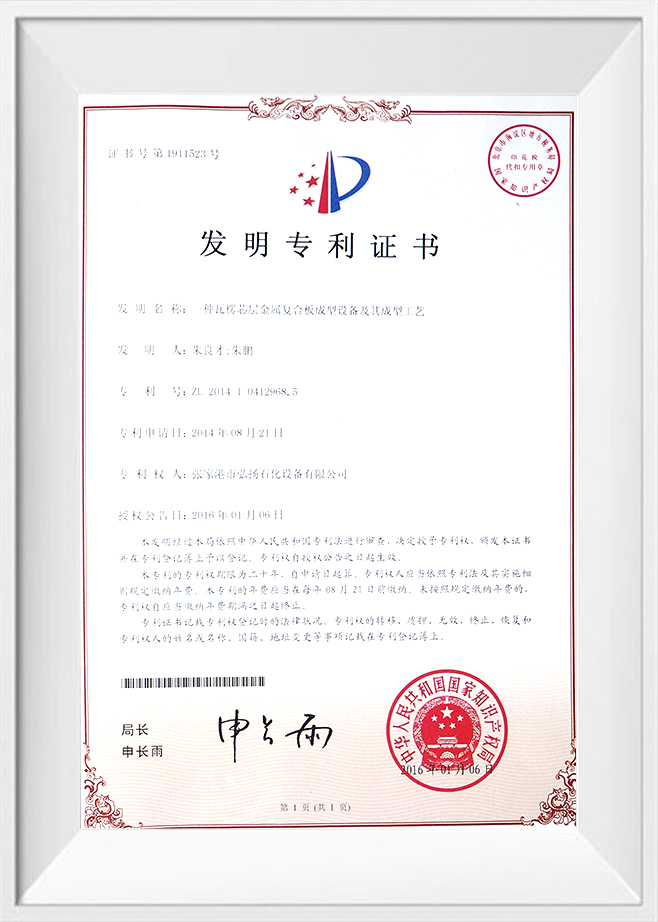

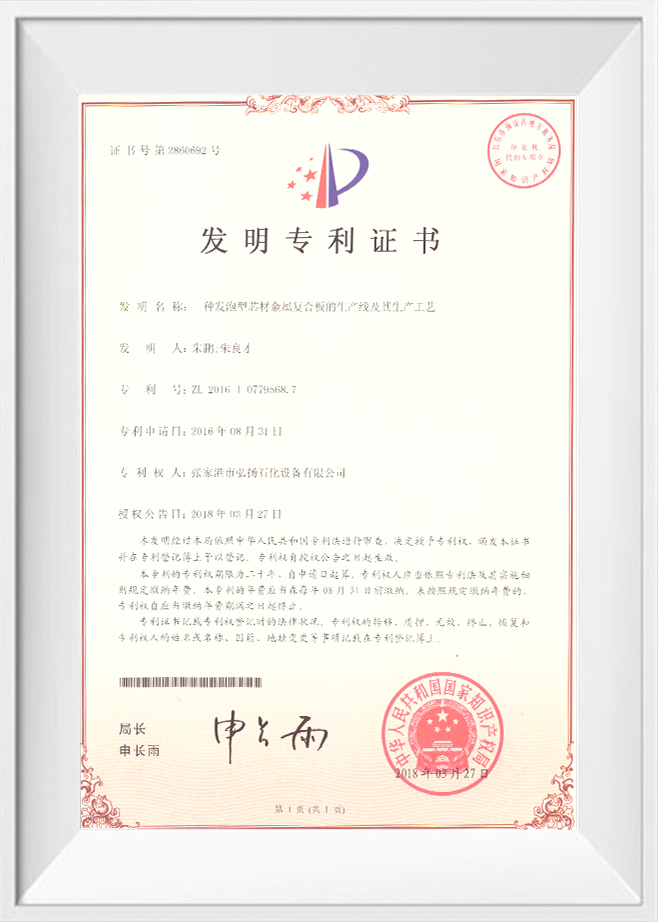

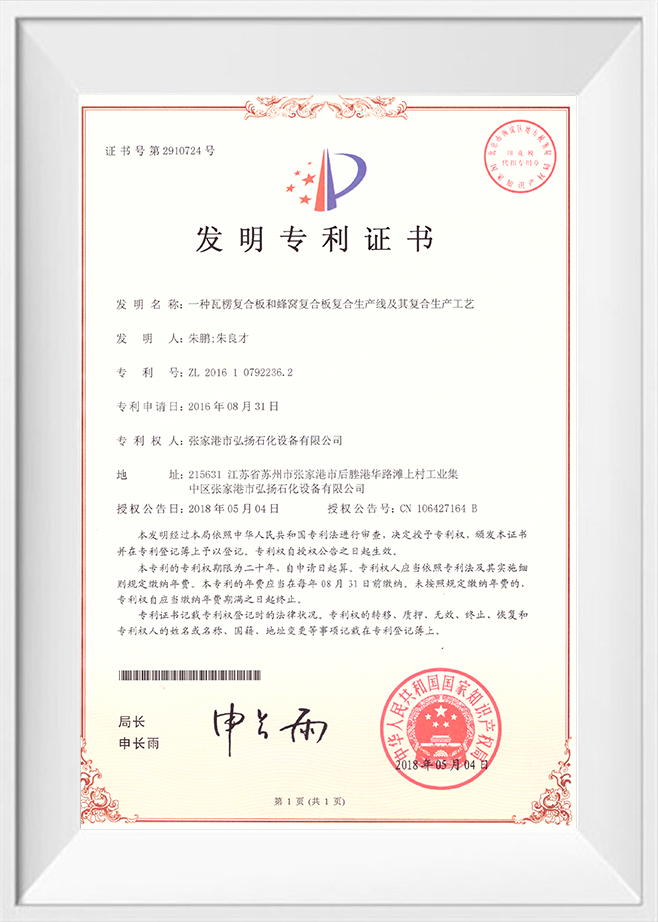

Based on the modular design concept, the auxiliary equipment can be customized according to customer’s production scale and product characteristics. For example, for customers with small production scale, a small coil decoiling machine (max coil weight 2t) can be provided; for customers producing extra-large size composite panels (length >6000mm), a lengthened core material cutting machine can be customized. The Suzhou Engineering Technology Research Center and Jiangsu Provincial Graduate Workstation of Hongyang Machinery provide technical support for customization, ensuring that the customized equipment meets production requirements.

III、Enterprise Support for Auxiliary Equipment

As a professional manufacturer of metal composite material intelligent equipment, Zhangjiagang Hongyang Machinery provides comprehensive support for Auxiliary Equipment:

Quality Guarantee: All auxiliary equipments are manufactured in accordance with ISO 9001 Quality Management System standards, and key components (such as servo motors, laser detectors) are imported from well-known brands, ensuring equipment service life (average service life ≥8 years).

After-Sales Service: The company provides a 48-hour global emergency response service for auxiliary equipment. If there is a fault, engineers can remotely diagnose and guide maintenance; if on-site service is needed, they can arrive at the customer’s site within the agreed time. At the same time, the company provides regular maintenance guidance and spare parts supply, ensuring that the equipment runs stably.

Systematic Solution: The auxiliary equipment is not sold independently, but is matched with the core production lines to form a systematic production solution. The company’s technical team will formulate the most suitable auxiliary equipment configuration plan according to the customer’s production process and needs, helping customers achieve the optimal production efficiency.

Up to now, Hongyang Machinery’s Auxiliary Equipment has been exported to 45 countries and regions together with core production lines, serving 14 of the world’s top 20 metal composite material manufacturers. It has become an important part of the company’s global metal composite equipment service system, providing solid support for customers’ efficient production.