+86-18862679789

admin@evertopest.com

In the modern panel manufacturing industry, waste management has transitioned from a logistical burden to a strategic opportunity. The Offline Crusher is an environmentally friend...

View MoreAs the global manufacturing sector shifts toward materials that offer both high durability and low environmental impact, the PVC Foam Composite Panel Production Line has emerged a...

View MoreIn the competitive world of high-end material fabrication, the transition from manual assembly to a fully automated Aluminum Honeycomb Composite Panel Production Line represents a...

View MoreIn the rapidly evolving landscape of modern aerospace, marine, and high-end construction, the demand for materials that offer extreme strength without the burden of weight has rea...

View MoreIn the fast-paced world of modern manufacturing and logistics, the difference between a profitable operation and a struggling one often comes down to how efficiently materials move...

View MoreZhangjiagang Hongyang Machinery Equipment Co., Ltd. Product Overview

As a national enterprise dedicated to the R&D and manufacturing of intelligent equipment for metal composite materials, Zhangjiagang Hongyang Machinery Equipment Co., Ltd. provides a comprehensive range of high-quality products and systematic solutions for the global construction materials industry. Our product portfolio is carefully crafted to meet the diverse and evolving needs of the market, covering core production lines, auxiliary equipment, and raw materials, all backed by strong technological strength and industry expertise.

Metal Composite Panel Production Line Series

The Metal Composite Panel Production Line Series is the cornerstone of our product offerings, designed to deliver efficient, high-precision, and reliable production of various metal composite panels. This series encompasses a wide range of specialized lines tailored to different product requirements, ensuring that our customers can produce panels of superior quality with consistent performance.

One of the key highlights within this series is the A grade noncombustible fireproof composite panel production line. This production line is developed in strict accordance with the highest industry standards, particularly aligning with the requirements of the national standard 《Non-Combustible Metal Composite Panels for Architectural Decoration》, of which our company is a drafting unit. It is engineered to produce A grade noncombustible fireproof composite panels that possess exceptional fire resistance, thermal insulation, and mechanical properties. The line integrates advanced technologies such as precision transmission control, intelligent process monitoring, and modular design, which are derived from our three core technological platforms. These technologies ensure precise control of the production process, from material feeding and composite bonding to cutting and finishing, resulting in panels that meet or exceed the most stringent fire safety and quality criteria. Whether used in high-rise buildings, public facilities, or industrial structures, the A grade noncombustible fireproof composite panels produced by this line provide a reliable solution for enhancing fire safety and structural integrity.

In addition to the fireproof composite panel production line, the Metal Composite Panel Production Line Series also includes other specialized lines such as the aluminum honeycomb core metal composite panel production line and the multifunctional customized metal composite panel production line. The aluminum honeycomb core metal composite panel production line is capable of manufacturing lightweight, high-strength aluminum honeycomb composite panels, which are widely used in interior and exterior decoration, transportation, and aerospace industries due to their excellent rigidity, sound insulation, and corrosion resistance. The multifunctional customized metal composite panel production line, on the other hand, offers flexibility and versatility to meet the unique needs of customers. It can be customized to produce metal composite panels with different materials, thicknesses, colors, and surface finishes, including 3D aluminum-core metal composite panels that add a creative and aesthetic touch to architectural designs. Together, these production lines cover 12 categories of high-end metal composite panel products, providing customers with a one-stop solution for their production needs.

Aluminum Coil Color Coating Production Line

The Aluminum Coil Color Coating Production Line is another key product in our portfolio, designed to provide high-quality color coating for aluminum coils, which are essential raw materials for the production of metal composite panels and other aluminum products. This production line adopts advanced coating technologies and processes to ensure uniform, durable, and aesthetically pleasing color finishes on aluminum coils.

The line features a fully automated production process, from coil cleaning and pretreatment to coating application, curing, and cooling. The pretreatment stage effectively removes oil, rust, and other contaminants from the aluminum coil surface, ensuring good adhesion of the coating. The coating application process uses high-precision coating machines that can apply various types of coatings, such as polyester, fluorocarbon, and polyurethane, in different thicknesses and colors according to customer requirements. The curing stage employs advanced heating systems that ensure the coating is fully cured, providing excellent resistance to weathering, fading, scratching, and corrosion.

With the Aluminum Coil Color Coating Production Line, customers can obtain aluminum coils with consistent color quality, smooth surface finish, and long service life. These coated aluminum coils not only enhance the appearance of the final metal composite panels but also improve their durability and performance, making them suitable for use in various harsh environments, including outdoor architectural decoration, automotive parts, and home appliances.

Auxiliary Equipment

To complement our core production lines and ensure the smooth and efficient operation of the entire production process, we offer a comprehensive range of Auxiliary Equipment. These auxiliary equipment are carefully designed and manufactured to work in perfect harmony with our production lines, providing reliable support and enhancing overall production efficiency.

Our Auxiliary Equipment includes but is not limited to material handling equipment, cutting equipment, testing equipment, and packaging equipment. The material handling equipment, such as coil decoilers, straighteners, and feeders, ensures the smooth and accurate feeding of raw materials into the production lines, reducing material waste and improving production efficiency. The cutting equipment, including CNC cutting machines and slitting machines, enables precise cutting of metal composite panels and aluminum coils into the required sizes and shapes, meeting the diverse needs of customers. The testing equipment, such as fire resistance testing machines, mechanical property testing machines, and coating performance testing machines, allows customers to conduct strict quality inspections on the products during and after production, ensuring that the products meet the specified quality standards. The packaging equipment, such as automatic packaging machines and palletizers, provides efficient and secure packaging for the finished products, protecting them from damage during transportation and storage.

FR Raw Material

In addition to the production lines and auxiliary equipment, we also supply high-quality FR Raw Material, which is a critical component in the production of fireproof composite panels. Our FR Raw Material is carefully selected and tested to ensure its excellent fire resistance, thermal stability, and compatibility with other materials used in the composite panel production process.

We work closely with reputable suppliers to source FR Raw Material that meets the highest industry standards and regulatory requirements. Our FR Raw Material includes fire-resistant core materials, adhesives, and coatings, all of which are designed to enhance the fire performance of the final composite panels. The fire-resistant core materials, such as mineral wool, rock wool, and ceramic fiber, have excellent thermal insulation and fire resistance properties, effectively preventing the spread of fire and heat. The adhesives used in the composite panel production process are high-temperature resistant and have strong bonding strength, ensuring the structural integrity of the composite panels even in high-temperature environments. The fire-resistant coatings applied to the surface of the composite panels further enhance their fire resistance and durability, providing an additional layer of protection.

By providing high-quality FR Raw Material, we ensure that our customers can produce fireproof composite panels that meet the most stringent fire safety standards, while also maintaining the quality and performance of the products. Our commitment to providing high-quality raw materials is in line with our overall philosophy of "Quality as the Foundation, Pursuit of Excellence," ensuring that every aspect of the product production process meets the highest quality standards.

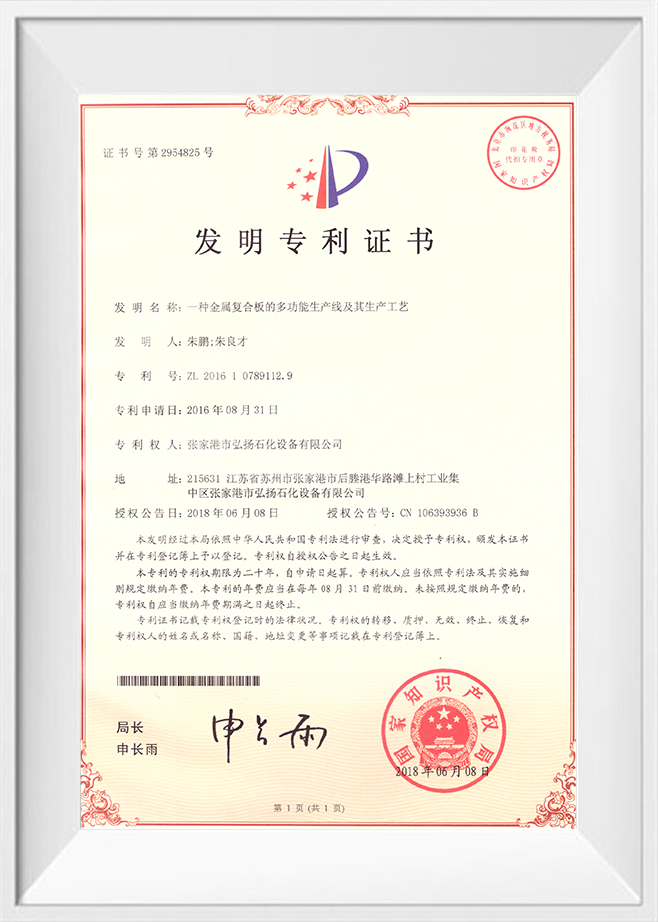

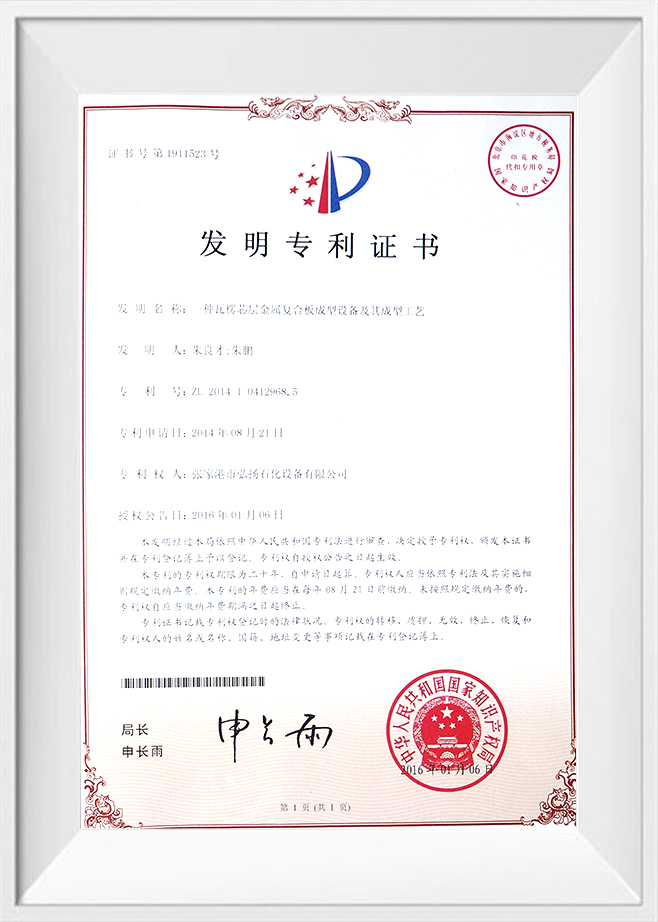

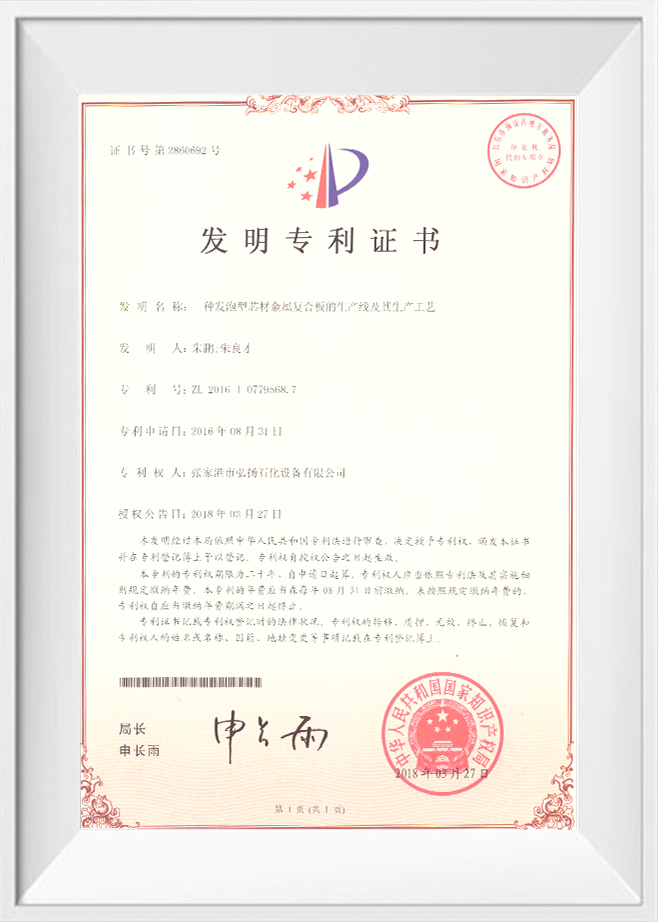

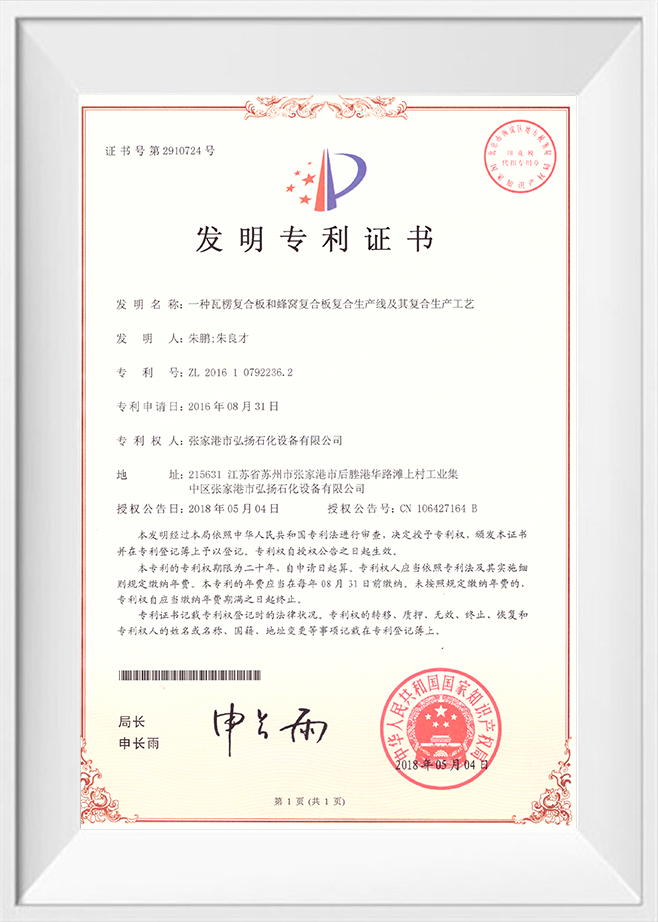

Backed by the Suzhou Engineering Technology Research Center and Jiangsu Provincial Graduate Workstation, we have established a strong technological R&D team that continuously drives innovation in our products. Our equipment has been exported to 45 countries and regions, including Europe, the U.S., the Middle East, and Asia-Pacific, serving 14 of the world's top 20 metal composite material manufacturers. We are certified with the ISO 9001 Quality Management System and CE Certification, ensuring that our products meet international quality standards. Additionally, we offer a 48-hour global emergency response service to provide timely support to our customers, and we have successfully reduced the equipment commissioning cycle by 30% compared to industry standards, helping our customers start production faster and gain a competitive edge in the market. With 70 core patents, we continue to lead the way in technological innovation in the metal composite materials sector.

Upholding our philosophy of "Quality as the Foundation, Pursuit of Excellence," Zhangjiagang Hongyang Machinery Equipment Co., Ltd. is committed to providing the global construction materials industry with high-quality products, advanced technologies, and comprehensive services. We strive to become a globally integrated service provider for metal composite equipment, contributing to the development and progress of the industry.